Continuous developments – efficient electronics manufacturing – flexible services

At ElektroMont, continuous development is a core principle of how we deliver efficient electronics manufacturing.

We consistently invest in technology, manufacturing capacity, and professional expertise to ensure our partners benefit from

reliable, scalable, and future-proof electronics contract manufacturing services.

Our experienced professionals regularly participate in specialized trainings to keep pace with the latest industry standards and technologies. This enables us to meet the highest customer expectations while adapting quickly to changing market demands.

We provide a wide range of high-quality services and deliver tailored solutions covering the full scope of electronics contract manufacturing – from prototype production to serial manufacturing and long-term product lifecycle support.

Flexibility, transparency, and long-term partnership are central to our customer management approach. We believe that efficient electronics manufacturing is built on stable processes, modern infrastructure, and close collaboration with our partners.

2025 – Development, modernization, and purposeful growth

Year 2025 at ElektroMont has been defined by targeted developments, technological modernization, and investments focused on long-term operational stability. These steps further strengthen manufacturing quality, production capacity, and predictable, reliable operations – key pillars of efficient electronics manufacturing.

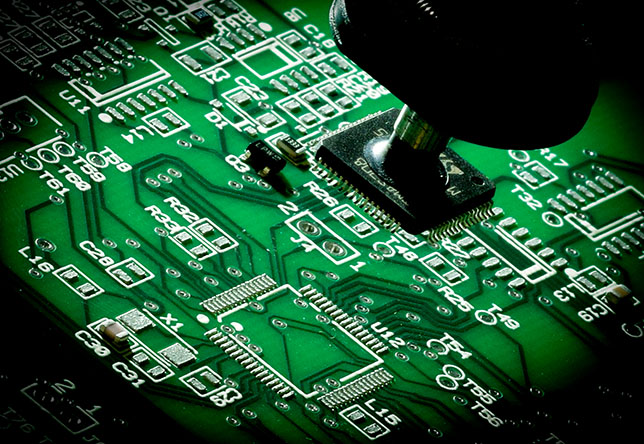

As part of our technology upgrades, we commissioned two Inertec CUBE.460 selective soldering systems, delivering even higher precision and consistently uniform soldering quality across complex assemblies. To increase SMT capacity and production speed, our machinery fleet was expanded with an additional Panasonic AM100 SMT placement machine, supporting scalable and efficient serial manufacturing.

Quality control capabilities were further enhanced with the integration of a high-resolution Phoenix X|aminer X-ray inspection system, enabling detailed analysis of hidden solder joints and complex components. In parallel, a Weller WXair rework station was introduced to support advanced repair and post-processing operations.

To improve service flexibility and logistics responsiveness, our company fleet was expanded with a new vehicle,

supporting faster and more reliable customer service.

Beyond equipment investments, we continued to develop our quality assurance systems, manufacturing workflows, traceability solutions, and automated inspection checkpoints. These improvements further reinforce stable, traceable, and reliable electronics manufacturing processes – ensuring consistent quality and long-term value for our partners

Technology upgrades built on real production needs

In line with market trends and traceability requirements, we introduced a state-of-the-art laser marking system in 2024. This individual PCB identification solution enables full traceability and end-to-end monitoring throughout the entire manufacturing process, following each printed circuit board from SMT assembly through its complete lifecycle.

To further improve manufacturing efficiency and quality in serial production, we expanded our capabilities with additional wave soldering equipment. The two wave soldering machines operated by ElektroMont support stable, repeatable, and high-quality production for a wide range of through-hole assemblies.

Proven investments in efficient electronics manufacturing

Between 2022 and 2023, ElektroMont completed investments totaling EUR 1,000,000, focusing on plant modernization, capacity expansion, and the development of our industrial park. As part of this program, we integrated advanced equipment including Panasonic SPG-2 printers, Panasonic AM100 automated assembly systems, Nutek loaders, unloaders and conveyors, Heller Industries reflow ovens, a Hawkeye 1000 X-ray component counter, and Mirtec 3D AOI inspection systems.

These continuous developments ensure that ElektroMont remains a reliable partner for efficient electronics manufacturing – today and in the future.