Development and Technological Transition

Opportunities Provided by the Company’s Own Site in Pásztó

In 2019, another milestone was reached in the life of ElektroMont with the purchase of the industrial park in Pásztó. This step towards independence opened up new opportunities for growth. Owning the site brought numerous advantages that were incomparable to those of a rented property.

At first, however, the size of the site exceeded the company’s operational needs, so the owners decided to lease out the unused areas. This was preceded by nearly a year of renovation and reconstruction, during which the industrial park buildings were made suitable for leasing.

“We spent a year on construction work to make the buildings ready for leasing. Soon after, we managed to lease 100% of the unused space. This not only made EMIP self-sustaining but also covered the loan repayments,” recalls Megyó.

In addition, owning the site provided a stable asset base for future investments, increased the company’s overall value, and significantly improved its creditworthiness.

Technological Advancements

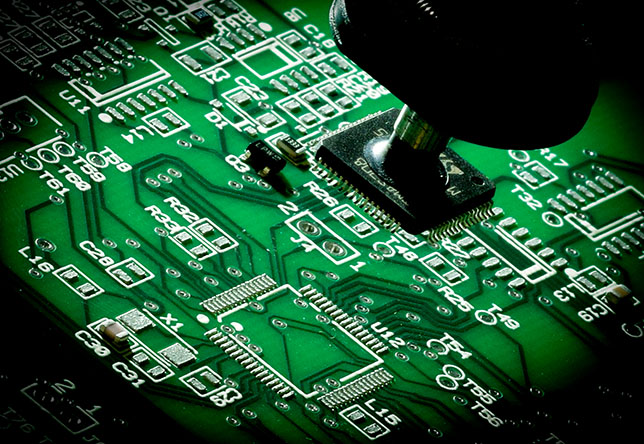

During the 2010s, ElektroMont continuously expanded its production capacity to meet the growing demands of its customers. In the early stages of SMT production, the production lines were built around second-hand but proven Samsung placement machines.

“Most of the equipment were Samsung CP60/62 and CP45 models, so expansions primarily increased capacity, but there was no real leap in technology yet,” explains Balázs.

The turning point came in 2018 when the company purchased its first next-generation Panasonic AM100 pick-and-place machine and a modern solder paste printer. By this time, the Samsung machines had become increasingly unreliable. While their speed was still adequate, their limited flexibility significantly restricted production processes, making the replacement of outdated machines necessary. In 2018, ElektroMont acquired its first Panasonic AM100 pick-and-place machine through a grant application, delivering the expected technological progress. In 2020 the purchase of two additional Panasonic AM100 units followed this.

This marked the beginning of the shift to modern SMT technology, which was followed by further acquisitions of new equipment. Behind these investments was a well-thought-out strategy, successfully secured grant funding, and the continuous reinvestment of the company’s financial results. Together, these ensured the renewal of the equipment fleet and contributed to the commissioning of the modernized production lines.

The DAB Project – A Promising but Unfulfilled Opportunity

In 2017, the company joined the Digital Audio Broadcasting (DAB) project, which aimed to modernise radio broadcasting and provide higher quality by replacing analogue FM/AM broadcasting with a modern digital system. The project was launched at European level, with numerous industry players – including ElektroMont’s strategic partners – participating. The technology promised the capability to serve more stations, improve sound quality, and enable additional data services (e.g., track titles, news headline etc).

The project prompted the company to significantly expand both its production and human capacities, preparing for mass production. However, the breakthrough never came: the EU ultimately did not mandate the adoption of the DAB system, leaving it as a recommendation only. The spread of the technology was further hindered by the rapid rise of online radio and streaming services. As a result, the project stalled in several European countries, including Hungary, leaving related industrial investments underutilized.

This experience again highlighted the importance of quick market adaptation and customer diversification – prompting ElektroMont to turn towards new partners and orders.

Business Development: Higher Added Value and Logistics Services

“From the very beginning, our goal was to perform activities with the highest possible added value. For a newly established service company, there were few opportunities for this, but over the years, as our experience and client base grew, this changed,” says Balázs.

In this spirit, the company began offering the full spectrum of device and key component manufacturing, while also developing its logistics activities intensively. Increasingly, partners took advantage of component procurement services, which not only offered convenience to customers but also supported optimal material supply for production.

Due to increased customer material and product flow, the development of the logistics equipment park also became necessary. This provided more flexible product handover options for numerous clients and enhanced material handling efficiency between the Pásztó plant unit and the Budapest office.

To further modernize material handling, the company installed a Hawkeye 1000 automated X-ray component counter in its warehouse, enabling precise part counting without opening the original packaging.

The Impact of the COVID-19 Pandemic – Challenges and Responses

The outbreak of the COVID-19 pandemic in 2020 posed serious challenges for the electronics industry. In addition to a decline in orders, supply chain disruptions – particularly from Asian suppliers, where factories completely shut down – caused significant stock shortages. Component prices rose sharply, delivery lead-times became unpredictable, and fulfilling orders precisely became increasingly difficult.

ElektroMont’s management responded quickly and proactively: the company was among the first to introduce remote work for office employees, while implementing strict hygiene measures in production areas (mandatory mask-wearing, social distancing, regular disinfection, and staggered shifts). Production could not be halted for even a moment, as the company remained committed to fully serving its customers – while prioritizing the health of its employees.

Although the situation could have justified layoffs, the company chose instead to reduce working hours in order to retain its skilled workforce. At the initiative of the management, executive salary payments were temporarily rescheduled. In some areas, the period between 2020 and 2023 even saw headcount growth.

The results spoke for themselves: after the pandemic subsided, ElektroMont quickly regained its capacity and was able to respond effectively to increased market demand.

Establishing the Current SMT Lines

The next major milestone in modernization came in 2022 with the complete renewal of the SMT lines. ElektroMont purchased three new pick-and-place machines, bringing the total to six Panasonic AM100 units. This meant that three out of the four SMT lines in the plant now operated exclusively with new equipment.

At the same time, additional new equipment was procured: SPG-2 printers, Nutek-manufactured loaders, conveyors and unloaders, an N2-capable Heller reflow oven, and Mirtec 3D camera-based AOI systems were commissioned. To ensure uninterrupted customer service, the new machines were gradually integrated into the production lines. As a result, the transition occurred seamlessly.

The old, used equipment was decommissioned simultaneously with the installation of the new systems, enabling ElektroMont to establish three fully automated production lines equipped with new machinery by 2023.

As a result of modernization, changeover speeds improved significantly, technical reliability increased, and the flexibility provided by the new equipment boosted production efficiency. Additionally, the capacity of the three new lines already exceeded the overall capacity of the four old lines.