Conformal coating as an efficient way of surface handling – manual and automated solutions

Upon individual customer needs efficient surface handling solutions ensure

the long term protection of assembled printed circuit boards (PCB)

Conformal coating, being a protective solution is of significant importance while protecting the assembled printed circuit boards (PCB) from moisture, heat, dust and other types of contamination. It provides long-term protection against mechanical abrasion as well. The properly used coating increases resistance and lifetime of both printed circuit boards and assembled components, thus of the manufactured final product as well. Besides, coating is efficient in preventing the PCB and components from defects caused by environmental conditions.

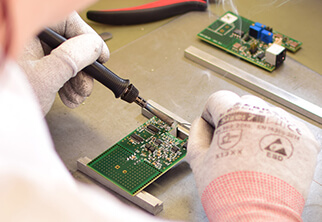

The protection of the electronic devices is ensured basically with manual coating upon individual customer needs. The technology used by ElektroMont enables full or partial coating of the SM- and TH-assembled printed circuit boards.

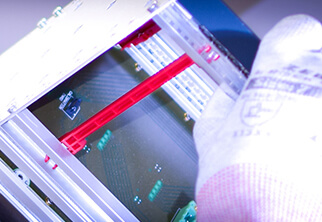

Along with manual coating our Nordson Conexis CX-3040 type automated coating machine increases the efficiency of serial production.

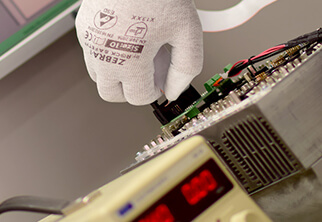

Using conformal coating is proposed following soldering and testing of each PCB due to its preventive nature.