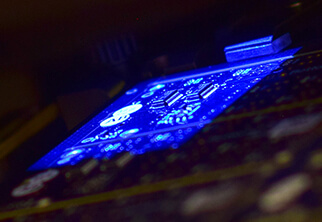

Optical and X-Ray inspection support high soldering quality

Perfect soldering quality of SM components is ensured with multi-level inspection. Inspections support the manufacturing of high-quality electronics devices.

A 3D camera AOI optical inspection is provided in case of each SM-assembled PCB. If necessary both optical and X-Ray inspection are provided.

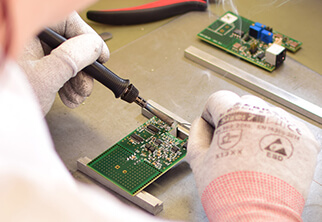

Optical (AOI) inspection

In order to ensure perfect soldering qusality an automated optical inspection (AOI) of each SM-assembled PCB is performed in case of each manufacturing process.

AOI process helps us in early finding and repairing soldering defectsA, thus increasing customer satisfaction.

Mirtec MV-3 OMNI 3D camera AOI inspection devices used by ElektroMont provide an efficient support in detecting incidental soldering irregularities of surface-mount assembled printed circuit boards. While using this technology most of the failures accured during SM-manufacturing can be detected and repaired on time. Such failures are e.g. inproper placing or absence of any SM-component, soldering defects or the partial or even full ansence of soldering material.

During automated optical inspection the following are examined:

- state of printed circuit boards,

- component differences,

- component polarity,

- presence or absence of components and their placement,

- excess or absence of solder,

- problematic bonding,

- damaged components,

- soldering defects, such as tombstones or bridges,

- presence of any foreign material on the PCB.

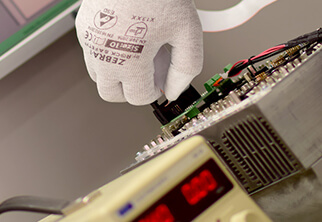

X-Ray inspection

In special cases or upon customer need an X-Ray inspection is executed as well. X-Ray is an optimal device for the detection of non-visible defects of electronics.

Detection of hidden failures of already assembled complex electronic devices on time may result in a significant cost decrease. Decreasing costs contribute to the increase in cost efficiency of manufacturing.

ElektroMont uses a Dage XiDAT XD7000 type X-Ray inspection machine in order to inspect non-visible solderings. This device is used for the determination of compliance or possible differences of any component as well. Using this technology, upon customer need, we do the inspection of the components purchased by the customer as well. The pictures taken are made available for them in oder that they can be sure if the component purchased is suitable for assembling or not.

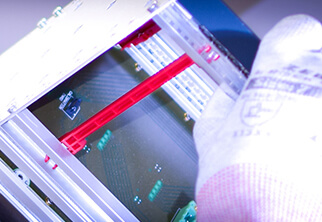

X-Ray inspection shows if the already assembled non-visible solderings of special components like IC or BGA have any defects or not. Besides it shows if there is insufficient or excess solder material or if any component has any such defect or missing part which are hidden from view. This inspection type provides a good opportunity to avoid problems, find planning failures during prototyping, prior to starting a serial production.