Quality surface-mount assembly service with fully automated SM-lines – no human touch

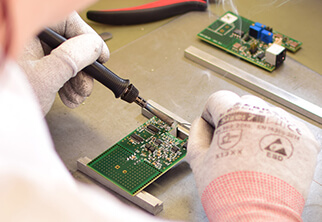

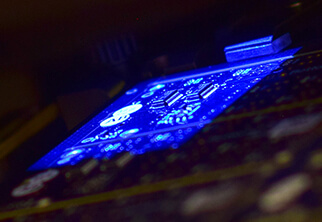

The high-quality and precise surface-mount assembly of printed circuit boards (PCB)

is ensured by the three equal, fully automated SMT manufacturing lines of ElektroMont.

The modern surface-mount technology used by ElektroMont enables the quick, precise and efficient assembling and soldering of up to daily 1,750,000 pieces of electric components on printed circuit boards (PCB).

Possible size of the PCB: 50×50 – 510×460 mm.

Possible size of the components: 01005 – 120×90 mm, 150×25 mm.

Prior to assembling our Panasonic SPG-2 automated printers apply the soldering paste onto the surface of the printed circuit boards having manufactured upon customer needs. The high-level soldering quality is ensured with stainless steel stencils and the type of the paste chosen following a long-lasting testing period.

Assembling of the SM-components – independent if they are placed in a tray, a tube or a reel – is performed by modern Panasonic AM100 automated assembling machines (so called Pick & Place machines).

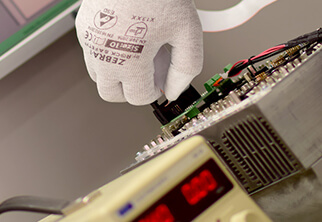

As a closing step of the surface-mount process soldering is completed by our Heller reflow oven (working in nitrogen athmosphere as well) based on the temperature profile determined by the paste manufacturer or a unique temperature profile taken upon individual request of the customer. The reflow ovens used by ElektroMont are of different length enabling temperature profile suiting of different types thus resulting in high-quality and tailor-made SMT-assembling.

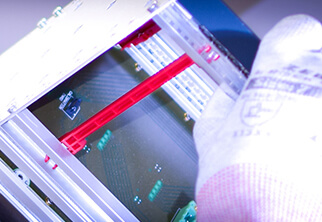

The safe moving of the printed circuit boards are guaranteed by special Nutek loaders, unloaders and conveyors within each manufacturing line, enabling the loading and moving of the panels without human touch.

In case of an individual prototyping need our vapour-phase surface-mount soldering machine is available for manufacturing purposes.