The Foundation and Early Days of Elektromont Kft.

The Beginnings and the Idea

Elektromont Kft. was founded by Balázs Fenyő and József Medgyesi (Megyó for those who know him), being the owners today as well. In the early 2000s, they worked together at a leading medical electronics company. At that time, Balázs was leading the Production Development Department, while Megyó served as the Production Director. The company primarily developed and manufactured its own electronic products but also took on contract manufacturing projects. After spending nine years together at the same firm, the founders began considering starting their own company in the spring of 2005. “The original idea was to use the experience we had gained to run a company, eliminate the failures we had encountered, and still make a living out of it,” recalls Balázs. Over the years, the founders identified market gaps and opportunities that provided a solid foundation for their first steps. The idea quickly formed: they would seize these new opportunities to start their own electronics manufacturing company and offer new services through their existing network that their employer did not provide.

The Foundation and First Steps

Thoughts quickly turned into action, and, at the initiative of Megyó, Elektromont Kft. was officially founded on May 9, 2005.

The new company started working with only 2-3 person, fulfilling the first orders from their initial clients. From day one, the owners worked tirelessly on developing the company and acquiring new customers and projects. Right from the beginning, they stepped beyond the classic role of a contract manufacturer by supplementing their production services with material procurement and logistics.

At the start of January 2006, significant changes took place:

- the company rented two 25 m² rooms at its current headquarters on Sztregova Street 1 in Budapest;

- the team grew with the addition of soldering specialists and a logistics coordinator;

- they became the primary strategic supplier for the Sarantel Geohelix Project, which significantly increased the initial order volume;

- they also won the continuation of the Integration RF Module project, which had played an important role at the company’s launch;

- they began working on several other sizable projects (e.g., GPS device manufacturing).

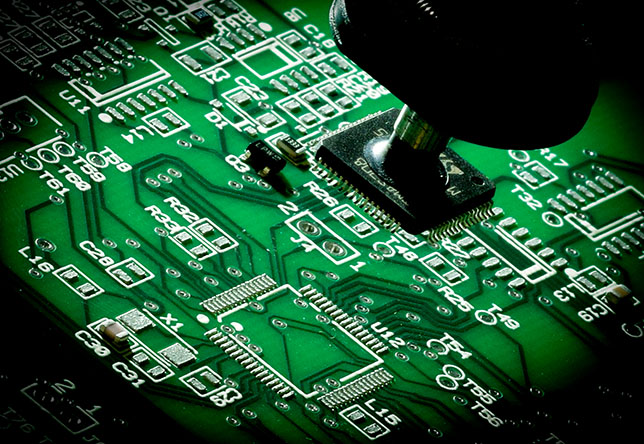

At this stage, the company handled only material procurement and traditional manual soldering, while SMT manufacturing was outsourced to a contract manufacturer due to the lack of automated assembly equipment.

“We thought these projects would last forever. But we were just lucky up until then,” Joci remembers.

Initial Growth and Investments

Encouraged by early successes, the founders made a decisive move: in summer 2006 they left their jobs and began working full-time at ElektroMont. They made a critical decision that continues to shape the company today: to rent their own facility, purchase production equipment, and become a full-service electronics contract manufacturer. They invested all their assets into purchasing equipment and renovating the leased property on Vegyész Street.

“We bought a DEK 265 SX printer, a Samsung CP60 with feeders, and a Heller reflow oven”, recalls Megyó. Balázs adds: “that Heller oven is still in use today.” “We were incredibly proud of those newly purchased used machines. On May 17, 2006, we signed a 3-year lease for about 300 m² of space, which we converted from a showroom into SMT and THT production areas, as well as offices. That summer, the machines arrived in several shipments and were installed by late July. We built and assembled worktables ourselves. We did everything by hand. At the same time, we hired more staff”, Megyó recalls.

Some of the employees who joined during this period still work at Elektromont today and play key roles in managing the company’s manufacturing operations.

“This was a great foundation for seeking new clients. Around the same time, we also started using ERP-software, which helped us with planning, inventory management, and cost tracking. From our previous experience, we knew that most failures stemmed from poor documentation, so we placed great emphasis on clear but simple documentation for our employees. Likewise, we prioritized implementing a quality management system. We obtained the ISO 9001 certification by the end of 2006”, adds Balázs.

„The First Collapse”

With investments and developments completed, everything was in place for further growth. But, as Megyó explains, “By the time the facility was ready, all of our projects collapsed for various reasons.” The Sarantel project paused for half a year due to excessive planning, the Integration RF Module project halted because of a software error on the client’s side, and the GPS project was phased out and not continued.

The founders found themselves with no major projects, holding a leased facility, newly acquired equipment, and an expanded team to finance.

Help arrived soon: several companies, which remain Elektromont clients today as well, placed trust in and began assigning more work to Elektromont. Although it was difficult, they managed to get through the period from late 2006 to mid-2007. In 2007, the Sarantel project resumed, and clients who had supported the company after the collapse also began increasing their orders.

The company began growing again: through a grant, it purchased a JT 450 wave soldering machine, leased a second SMT line (which was soon returned due to underutilization), and in 2008, acquired another used Samsung CP60 machine.

The next technological expansion took place in early 2009, when two new CP45 FV Neo machines arrived at the plant. „This upgrade increased our capacity, but also improved quality – even though the CP45 was slower, it handled larger and more precise components more accurately than the CP60. Compared to today’s Panasonic AM100s, these assembly machines were significantly slower. Another disadvantage was that, due to technological advancement, they couldn’t handle the increasingly smaller component sizes. Officially, the smallest supported size was 0603. The issue wasn’t so much accuracy, but rather the component scattering of the machine”, Balázs explains.