Soldering of TH-components – efficient through-hole assembly

ElektroMont offers its customers basically traditional manual through-hole soldering services. Besides automated TH-assembly solutions for the efficiency of electronics manufacturing are provided as well.

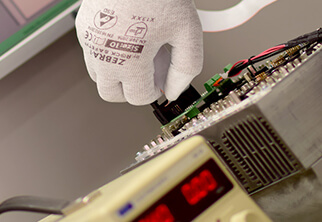

The traditional, so called through-hole electric components are basically soldered to printed circuit boards in a manual way. This manual through-hole assembling technology used while assembling and soldering TH-components ensures an extremely strong mechanical bond. Other advantage of this technology is that the quality of soldering can be visually inspected as well.

Manual soldering is implemented by our experienced, well trained employees. They have enough knowledge for the fast identification of problematic components resulting in preventing soldering inaccuracies.

In special cases ElektroMont applies automated soldering solutions as well besides the manual one. While serial production automated solutions result in increased manufacturing efficiency.

Wave soldering – Automated serial manufacturing

If size of the serie and planning of the circuit board makes automation possible, then wave soldering is the most efficient automated bulk through-hole soldering solution. Besides it is an optimal solution for the the soldering of PCBs having a high volume of TH-components or having a large size. Wave soldering ensures an accurate soldering quality in case of both one- and double-sided printed circuit boards. In HB HW350-N-450 and Vitronics DELTA5 types of wave soldering machines used by ElektroMont conveyors move the PCBs already placed with TH-components between different zones: from flux application through the pre-heting zone until the solder wave.

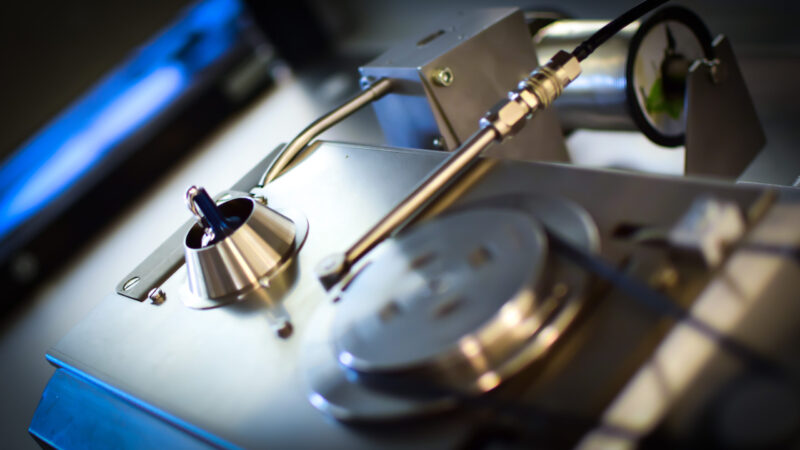

Selective soldering – automated through-hole soldering solution for components difficult to reach

For prototyping reasons or small series selective soldering technology is an optimal solution. Selective soldering ensures perfect bonding and fulfills IPC 610 standard prescriptions. This is a safe technology in case that components to be soldered are surrounded and close to components already surface-mount assembled in order to avoid damaging these SM-components. ElektroMont uses two brand-new Inertec CUBE.460 and an EBSO SP400NC type of selective soldering machine.