From Budapest to Pásztó

The Birth of the Pásztó Plant

As a result of the projects restarted after 2007, ElektroMont began to exceed the production capacity of its Budapest facility.

In 2008, the company’s largest client decided to relocate its own operations to Pásztó, therefore purchased a property at 149 Fő Street. Still one of ElektroMont’s key strategic partners today, the company required a reliable contract electronics manufacturer to fulfill its orders, and thus offered ElektroMont the following: it would build a 600 m² production facility for them and outsource a significant portion of its manufacturing.

“The facility (which is now the current ElektroMont SMT plant) consisted of a fully renovated building section and complete supporting infrastructure,” recalls Megyó. “This setup offered further advantages, including reduced logistics costs. The electronics warehouse was located on the manufacturing site, so we had access to all the necessary components for circuit assembly, and finished PCBs only had to be wheeled through one door,” adds Balázs.

The First Manufacturing Line in Pásztó

At the end of 2008, construction began on the new ElektroMont plant in Pásztó, along with training for local staff in SMT machine operation and logistics. Several colleagues who joined the company at that time remain members of the ElektroMont team to this day.

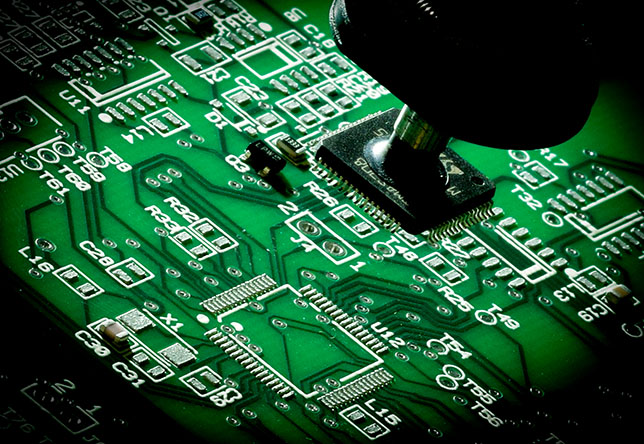

With the support of a 2008 grant, ElektroMont acquired two Samsung CP45 NEO placement machines, two PDT AOIs, a Heller reflow oven, and two DEK 256SX printers. These were added to the two existing Samsung CP60 machines, giving the company two fully equipped production lines that met its partner’s expectations.

The first production line in Pásztó was assembled in spring 2009. A JT 450 wave soldering machine, already in use in Budapest, was relocated to the new plant, and production at the new site commenced. By that time, the company had 19 employees.

By summer 2009, the Pásztó plant received ISO 9001 certification and was officially inaugurated.

The New THT-plant and Expansion

The owner of the Pásztó site continued to provide increasing volumes of work to ElektroMont, and over time it became necessary to employ a dedicated manual-soldering team. Together with its strategic partner, the company selected and trained the most suitable individuals for the job.

One of Pásztó’s main advantages was its expansion potential and enabling ElektroMont to lease more and more space as demand increased.

Following the installation of the first SMT line, expansion of the automated production capabilities quickly became relevant. Initially, the company performed production exclusively for its strategic partner at this new site.

Later that year, ElektroMont acquired its first used Panasonic line, originally intended for the Budapest facility. However, the new (third) line required more space, prompting an expansion of the Vegyész Street site. The company leased a new area and developed a 500 m² production hall along with a two-storey, 200 m² office. The transformation and setup were completed before the equipment even arrived. A warehouse for storing raw materials was also established. At that time, production in Budapest accounted for approximately one-third of total capacity.

The First Storm

Unfortunately, reality did not match initial expectations: the increased automated capacity and the expanded workforce in Pásztó did not reach projected utilization levels. To maintain continuous manufacturing load, ElektroMont had to seek new orders. At that time, the company still believed a few major clients were enough for success. As a result, the 2010–2013 period was extremely challenging.

In 2013, the Sarantel project gained new momentum, with increased production and a broader product portfolio. ElektroMont committed to creating a new plant section in Pásztó and acquiring the necessary machinery for the project as well. The number of employees had increased to 51, which was nearly three times the headcount in 2009. All signs pointed to recovery – until the client unexpectedly filed for bankruptcy, failed to settle outstanding invoices, and ceased further orders. The company was left with a completed investment, a huge amount of receivables, mounting debts, and a looming international legal dispute (as injured) – all without new business.

By 2014, the situation became critical: the high rental costs of the Budapest facility became unsustainable. Order volumes fell short of expectations, and the burden of operations increased. The “dual-location” setup – with two warehouses, split equipment, divided expertise, and difficult capacity planning – made matters worse.

“It was a life-threatening situation. We were centimeters away from bankruptcy. By 2014, we were already running at a loss,” recalls Megyó.

The owners then made a crucial decision they hoped would stabilize operations by cutting costs: they closed the Budapest production site.

All equipment and inventory from the Vegyész Street facility were relocated to the new plant in Pásztó, and the lease was terminated. Some employees accepted the commute and continued working in Pásztó; others found work with one of the company’s clients, while a few secured new jobs elsewhere.. The remaining part of the Budapest division moved to its current headquarters on Sztregova Street 1, where a smaller office, a THT cell, and a warehouse were established.

Recovery

The crucial decision taken by the owners, the relocation of the whole manufacturing process to Pásztó proved to be the right move and ElektroMont successfully survived the crisis.

Other major projects were launched, breathing new life into the Pásztó plant – production resumed, and machine utilization significantly increased.

Encouraged by the successful partnership, a client expressed interest in acquiring a stake in the company, but the owners, guided by strategic considerations, ultimately declined – thereby preserving ElektroMont’s independence.

By this time, the owners had abandoned their earlier approach of relying on a few major clients. One of their most important strategic decisions during this period was to diversify: regardless of size, they aimed to collaborate with a broader range of partners.

This shift gave rise to new client relationships, many of which remain part of ElektroMont’s stable customer base today.

At the same time, the company continued its rationalization efforts: it concentrated all production in Pásztó, closed its Budapest warehouse and THT cell, and maintained only a small office in the capital.

Thanks to these strategic decisions and organizational changes, by 2017–2018 ElektroMont had stabilized and regained strength.

Acquisition of the Pásztó Site

“In 2018, the idea emerged that everything should be focused in Pásztó. Negotiations began, and we started seriously considering acquiring the site.

In April 2019, EMIP (EM Ipari Park Kft.) purchased the entire Pásztó industrial park from Innopark Pásztó Kft., paving the way for 100% of our operations to be based in Pásztó,” says Megyó.

With this decision, the owners committed to the Pásztó micro-region, which stabilized the company’s position and laid the foundation for further expansion and development.