FullHigh-QualityProfessionalReliable PCB Assembly

from Planning through Manufacturing to Delivery

Outsourcing electronics manufacturing is the first step toward efficient and long-term scalable electronic production.

At ElektroMont, electronics contract manufacturing is a controlled, end-to-end PCB Assembly process.

From design through manufacturing to final delivery, we keep quality under full control.

Because we believe that reliable products are built on uncompromising execution.

Our PCB Assembly Services

Fully automated electronics contract manufacturing

Whether for prototypes, small batches or high-volume production, our three state-of-the-art, fully automated SMT lines ensure soldering quality compliant with IPC standards.

Our modern pick&place machines are capable of assembling up to 875,000 SMD components per shift.

Our reflow ovens guarantee consistent and reliable soldering for both single- and double-sided PCBs.

READ MORE

.

Multi-stage inspection for flawless PCB assembly

After SMT assembly, every PCB undergoes automatic optical inspection (AOI), ensuring consistent PCB assembly quality across all production volumes.

Our high-resolution 3D inspection systems verify:

• solder joint quality;

• component placement;

• polarity and component values.

For hidden solder joints, X-ray inspection is applied, which can also be used for post-production fault analysis of previously manufactured PCBs.

READ MORE

.

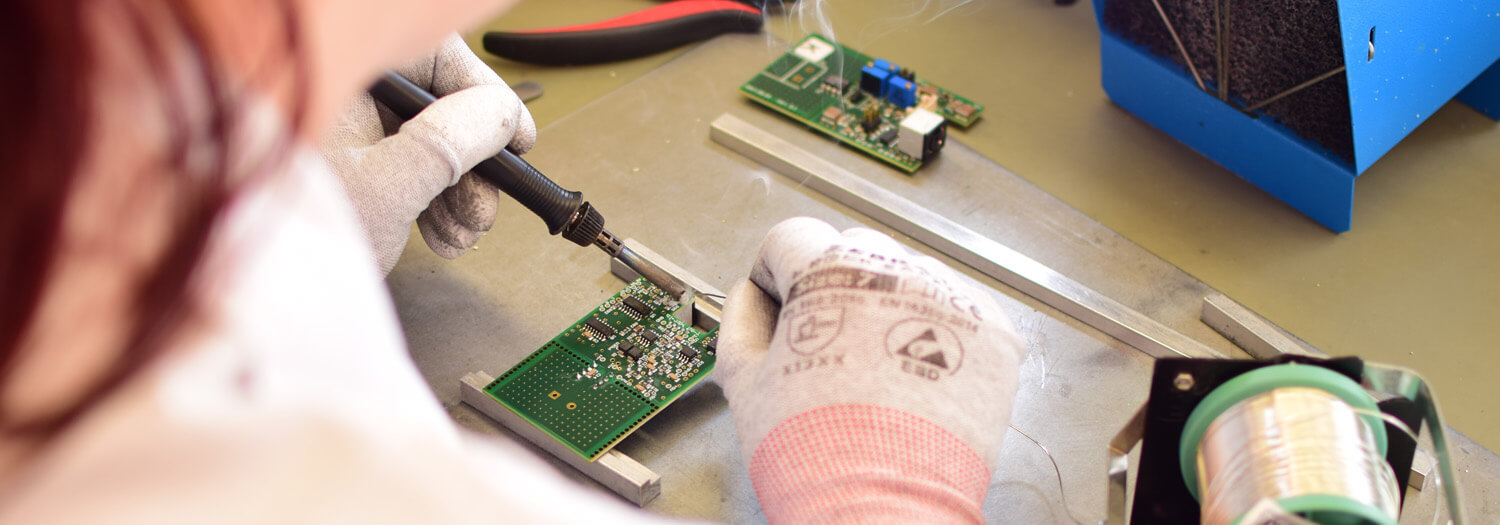

Insertion and soldering of through-hole components

For small series or low component counts, through-hole components are assembled using manual soldering by skilled technicians.

To increase efficiency, we also apply automated solutions:

• wave soldering for fast and precise assembly of large quantities of THT components;

• selective soldering for densely populated boards.

READ MORE

.

Functional testing, firmware upload and product commissioning

Our qualified technicians utilize customer-provided test environments and perform functional testing.

As part of electronics contract manufacturing, we also carry out:

• firmware upload;

• programming;

• documentation of test results.

Test data is available via cloud-based systems, with optional immediate access and sharing.

READ MORE

.

Conformal coating – long-term protection even in harsh environments

To protect assembled PCBs against moisture, heat, contamination, and mechanical stress, we apply conformal coating.

Our technology allows:

• full-surface coating;

• selective coating;

• manual or automated application.

Proper surface treatment significantly extends product lifetime.

READ MORE

.

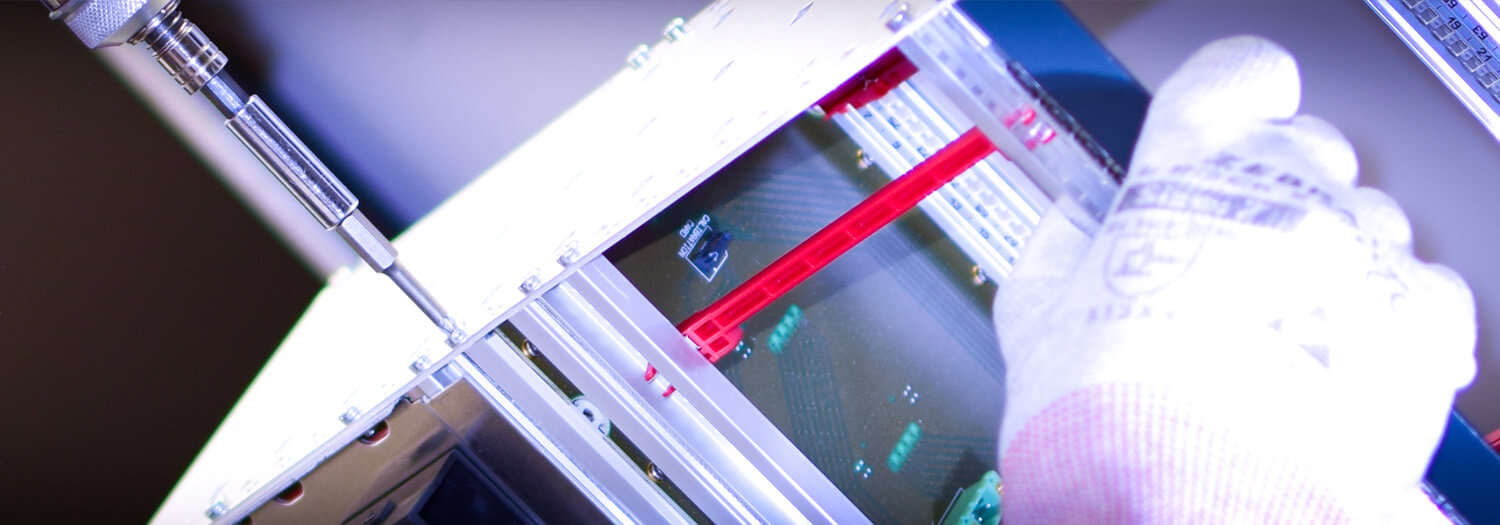

Assembly of custom cables, subassemblies and finished devices

Upon request, we provide:

• custom cable harnessing;

• cable assembly;

• final assembly of subassemblies and devices.

Following SMT and THT assembly, we handle final integration and enclosure, delivering products ready for immediate sale.

READ MORE

.

Why choose us?

Elektromont

– More Than a Partner!

PCB Assembly – quality that matters

Our modern machinery, skilled workforce and efficient process management ensure consistent, reliable quality in PCB assembly and final product manufacturing, from prototype to mass production.

With technical consulting and decades of experience, we support our partners long term in achieving cost-efficient manufacturing.

High-Quality PCB Assembly!

StableGlobalActive Market Presence

We demonstrate our expertise across multiple industries every day, delivering electronic products to 14 countries worldwide. Our growing base of satisfied partners and international customers is a testament to our reliability.

ENTRUST US WITH YOUR ELECTRONIC PRODUCT!